Blog

CUSTOMTOOLS Blog ArticlesIntegrating SOLIDWORKS and PDM to Microsoft Dynamics 365 Business Central ERP

Integrating SOLIDWORKS and PDM to Microsoft Dynamics 365 Business Central ERP

Nov 13, 2023 12:00 am (CET)In an era where technological integration forms the backbone of efficient business operations, connecting CAD, PDM, and ERP systems is a logical choice. This blog post is inspired by a recent webinar I hosted, which delved into the world of integrating SOLIDWORKS and SOLIDWORKS PDM with Microsoft Dynamics 365 Business Central ERP. The insights shared here aim to go beyond the specificities of this integration, offering a broader perspective on the synergy between CAD, PDM, and virtually any ERP system.

Before we begin, I'd like to provide you with some insights into my agenda today. There are 5 topics:

1. What is CUSTOMTOOLS?

2. Why are software integrations important?

3. How does the integration between SOLIDWORKS, PDM, and Business Central work?

3. How does a typical integration project go?

4. How did we help a Canadian Aquatic Play Solutions company with SOLIDWORKS and ERP Integration?

5. How does CUSTOMTOOLS pricing work?

Now let's get started!

What is CUSTOMTOOLS?

Not everyone may be familiar with CUSTOMTOOLS and what it truly offers, its benefits, and the team behind this exceptional product. CUSTOMTOOLS is an add-in designed for both SOLIDWORKS and SOLIDWORKS PDM. It made its debut in the late 1990s and has been a valuable tool for designers ever since. This powerful tool boasts a wide range of features, with a particular focus on advanced custom property management, batch operations like batch printing and batch file export, Excel-based reporting, and seamless ERP integrations. [If you want to know more about these, dive into our Capabilities page.]

The impact of CUSTOMTOOLS is remarkable, as it can significantly reduce the manual, repetitive aspects of design work by up to 3 0%. Moreover, it ensures consistency and helps eliminate common errors in the design process.

Behind CUSTOMTOOLS is the dedicated team at ATR Soft, a company headquartered in Turku, Finland, comprising 60 software development professionals. Our team has extensive experience in developing and maintaining PDM and PLM systems, as well as creating add-ins for CAD and PDM. Additionally, we are recognized experts in the field of software integrations. [You can read more about our knowledge from the Services page.]

So, in a nutshell, CUSTOMTOOLS is your go-to solution for enhancing your SOLIDWORKS and SOLIDWORKS PDM experience, and the ATR Soft team is here to support you on your journey to optimized design and productivity.

Why are software integrations important?

The reality is that companies operate with a variety of different systems that must communicate effectively to ensure smooth operations. The key point is to make life easier. Integration of these diverse systems allows for the automatic transfer of data from one system to another, eliminating the potential for human errors and enabling designers to work within a unified environment rather than constantly switching between systems.

From a technical perspective, software integration involves the process of combining separate software systems or components into one system, often leveraging their Application Programming Interfaces (APIs). This fusion of distinct systems facilitates the seamless exchange of data for various purposes. When it comes to software integration, there is no one-size-fits-all approach. I frequently encounter inquiries from customers about integrating with various platforms such as SAP, Dynamics NAV, Odoo, Epicor, Sage, and more. Before committing to any integration, I always ask for clarification on what precisely they mean by 'integration.'

The simplest and least automated form of integration that comes to mind is to use a clipboard. For instance, if a designer needs the next available drawing number from an ERP system, they can simply access the ERP, select the number, and copy it using Ctrl + C, then paste it into their CAD or PDM environment using Ctrl + V. While this method may not be highly automated or sophisticated and could potentially introduce errors, it is straightforward and cost-effective to implement.

It's worth noting that the level of automation directly correlates with the complexity and, consequently, the price tag associated with an integration project.

How does the integration between SOLIDWORKS, PDM, and Business Central work?

In the case of CUSTOMTOOLS, our integration with Dynamics 365 follows a traditional point-to-point approach. This means the integration boasts low latency and offers virtually limitless customization possibilities. Conversely, integration platforms tend to be easier to maintain and more scalable. At CUSTOMTOOLS, we've invested significant effort in ensuring that our integrations are not only functional but also highly maintainable.

CUSTOMTOOLS seamlessly operates within both SOLIDWORKS and SOLIDWORKS PDM. It serves as an invaluable extension to SOLIDWORKS PDM, empowering you with efficient and highly adaptable file conversions and ERP integrations. A common misconception is that you must choose one over the other, but the reality is that both systems have their unique strengths.

For those seeking Dynamics 365 Business Central integration, CUSTOMTOOLS offers an add-on solution. This integration supports not only older on-premise Dynamics NAV versions but also the modern cloud-based Dynamics 365 Business Central. It's built on official web services, ensuring robust data read and write capabilities. Furthermore, it accommodates various authentication options, including the traditional Basic Authentication, Windows authentication for on-premise installations, and the oAuth2 protocol-based authentication for cloud-based systems, aligning seamlessly with Microsoft's online services.

It's essential to recognize that no two integrations are alike, as every company operates differently, each with its distinct processes. As mentioned earlier, integration should be tailored to your company's workflows, precisely defining where data is created, needed, and maintained.

In CUSTOMTOOLS, we achieve this by developing customer-specific integration logic through script add-ins. These add-ins are centrally managed and automatically deployed to all client machines, ensuring consistency and simplifying modification processes. Leveraging the official and public CUSTOMTOOLS API, these script add-ins remain compatible with future CUSTOMTOOLS versions.

In summary, CUSTOMTOOLS offers a versatile and adaptable solution that seamlessly integrates with SOLIDWORKS, SOLIDWORKS PDM, and Dynamics 365 Business Central, all while tailoring the integration to your unique business processes.

One crucial principle to consider is how you want information to flow within your workflow. You have several options: it can flow from your ERP system to CAD, from CAD to ERP, or in a bidirectional manner, where information flows seamlessly in both directions. In our scenario, we maintain all data constraints within a single system.

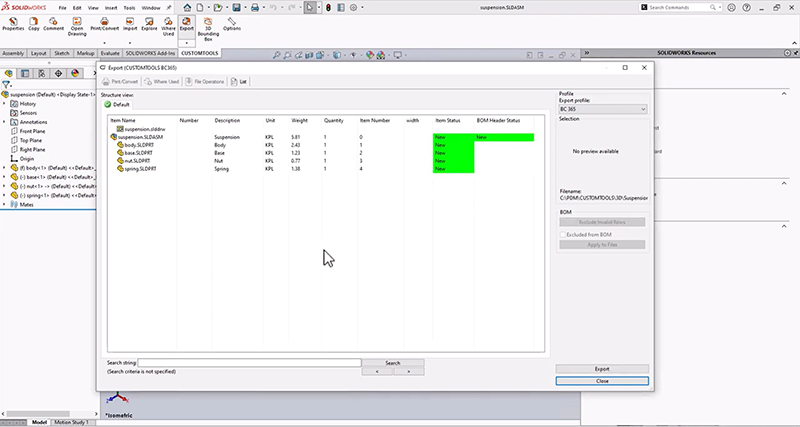

For instance, a list of available units of measures is maintained in ERP and retrieved from there for the designer to choose from available values. This approach ensures data integrity by consolidating it in a single location. CUSTOMTOOLS further enhances this process by allowing the automatic consumption of drawing numbers from the ERP system while creating a new CAD file. Individual parts and assemblies within the CAD system correspond to items within the ERP system. Conversely, an assembly Bill of Materials (BOM) created in CAD can be seamlessly transferred to the ERP system as a production BOM.

Moreover, we facilitate the export of SOLIDWORKS drawings to PDF format, which can then be conveniently attached to related items in the ERP system. Additionally, you can search for existing items directly from within the CAD user interface, streamlining the process of populating custom properties with item information from the ERP system.

With CUSTOMTOOLS, configuring your connection and authentication to your ERP system is a breeze. What's more, you can define all the necessary settings through our user-friendly interface, eliminating the need for coding, script writing, or tinkering with configuration files. No need to memorize ERP fields or record names; you can conveniently select them from a list. This seamless approach simplifies the process of mapping SOLIDWORKS Custom Properties with their corresponding item records in the ERP system.

But that's not all – you can also search for existing items and populate custom properties with information directly from the ERP. This feature proves invaluable when the item you're modeling already exists in your ERP system. Subsequently, when you export your Bill of Materials (BOM) from SOLIDWORKS or PDM, missing items are automatically created, and existing items are updated according to your specified settings. This same streamlined process applies to production BOMs.

CUSTOMTOOLS doesn't stop there – it also attaches a preview image of your SOLIDWORKS file to the item in the ERP, providing a visual representation of the item. Additionally, you have the flexibility to attach related files, such as PDFs generated from item drawings. It's worth noting that all files exported to the ERP are generated in the background if they're missing, ensuring that you're always working with the latest versions of your files.

If you want to see a demo of CUSTOMTOOLS ERP Connector, visit our YouTube channel and check out the webinar about this topic. The demo part starts at 16:47.

Recognizing that each company has unique integration requirements, we offer the flexibility to tailor the integration to your specific processes. The list of features we've implemented is extensive, covering a wide range of needs. This includes item variants, seamless data migration, effective handling of revisions, utilizing item templates, creating BOM versions, establishing item routings, managing item attributes, and handling language translations, just to name a few.

How does a typical integration project go?

We initiate every project with a comprehensive specification phase, collaborating closely with our clients to establish the fundamental principles of the integration. This phase encompasses critical aspects such as the potential migration of existing data, defining data mappings, and, most importantly, determining what data holds paramount importance in transferring seamlessly between systems, as well as how this data aligns across different platforms.

Following this careful planning phase, we transition into the implementation stage. Sometimes, we first carry out implementation in a test environment, but in many cases, clients exclusively possess a production environment. To configure and deploy the integration effectively, it is imperative for us to gain access to the client's environment.

Throughout the implementation process, we concurrently undertake testing and documentation, a practice that begins during the specification phase but reaches its zenith when all the requirements are implemented. This culminates in final testing, followed by comprehensive user training. We firmly believe that even the most sophisticated integration is only as powerful as the users who understand how to leverage it. While our systems are designed to guide users in the desired direction, a profound understanding of how the integration operates and its underlying principles remains crucial.

Lastly, but by no means the least important, we value the process of gathering feedback from users after the integration has been in active use. It's often challenging to account for every possible scenario during the project's early phases. Post-implementation insights might reveal the need to transfer specific data between systems, which can be accommodated through necessary adjustments. This continuous feedback loop ensures that the integration evolves in line with your evolving needs.

Customer Success Story: Vortex

Vortex, Aquatic Play Solutions, is a company founded in 1995 in Canada. They have revolutionized the way children and families play in urban spaces, waterparks, and resorts worldwide. Serving municipalities and private organizations, it has created over 8,000 custom installations in 50 countries and 5 continents. The mid-sized design project takes about one month and is built with 2,000 items.

Their design process used to be time-consuming and rigid. They have many requirements to fulfill in projects from a regulations perspective but yet the playgrounds need to be creative with product design and colors, and this also helps to differentiate Vortex solutions from its competitors. They have many color variants to manage, and sometimes customers want to change the requirements during the project such as changing material from galvanized steel to 316.

When Covid came, there was a good opportunity to improve the processes and the systems. Vortex chose ATR Soft as their integrator partner, and CUSTOMTOOLS was selected to implement the integration. Later on, Vortex started to use other features of CUSTOMTOOLS.

In CUSTOMTOOLS ERP Connector Vortex especially values the file links to SharePoint that are automatically generated to Business Central and can be then easily shared with third parties. The customization work started small but increased when the possibilities and benefits started to be uncovered. Overall, our team built 12 customized features to support the design process in SOLIDWORKS.

The outcome was that the whole design process sped up from 8 weeks to 4 to 5 weeks. Vortex is now able to react to customer needs quicker, deliver customer projects faster, and use the time saved for new product development. CUSTOMTOOLS is also helping to catch pre-production errors when exporting items to ERP, which prevents costly errors in production.

Pricing of CUSTOMTOOLS integration

Want to speed up the design process, as Vortex did? It is time to look at the pricing.

As Dynamics 365 Business Central integration is built on top of CUSTOMTOOLS platform, all integration users need a CUSTOMTOOLS Professional license whether they are using SOLIDWORKS CAD, PDM, or both. One license covers both systems on a computer. You also need the actual integration module, ERP Connector, which comes in 10 user bundles.

For the CUSTOMTOOLS licenses you only pay once. CUSTOMTOOLS support and ERP Connector subscription fees are reoccurring. You can check up-to-date price information from our Pricing page.

In addition, we need to implement the integration. A typical question at the very beginning is how many days it typically takes to make an integration project. That question is as tricky as the question of how many days it takes to build a house. The level of automation typically defines the level of complexity which on the other hand affects project size.

Summary

In conclusion, when it comes to integrations, the primary objective is to simplify our lives. There's no one-size-fits-all solution; each organization must carefully consider what information is vital to move seamlessly between systems and tailor their approach to meet their unique communication needs.

Additionally, it's crucial to bear in mind that a sustainable integration solution is built on a maintainable product or platform. Over time, changes in the ERP system may require updates to the integration logic. For example, new mandatory data fields or records may be introduced. To address this challenge, CUSTOMTOOLS offers a cost-effective, productized integration solution that can be easily customized to meet specific customer requirements, all while ensuring the continued maintainability of the integration.

Ultimately, the key is to embrace integration as a means to enhance efficiency and effectiveness, while ensuring adaptability for the ever-evolving needs of your organization.

How to get started?

Now you may wonder how to get started.

First, you should ask yourself what information I’m trying to collect or push to another system. If that sounds challenging to you, we can help you to formulate those ideas first. Sometimes it’s hard to imagine all the possibilities in the first place as we just learned from the Vortex case. Many times, it’s good practice to start small and grow over time.

Nevertheless, whatever your strategy is we are here to help you. You may contact us at sales@customtools.info, browse our website, and fill in the contact form under the header CAD-PDM-ERP integration on our Services page to describe your needs, or book a meeting from our calendar!

Author:

Tero Salonen, Product Director